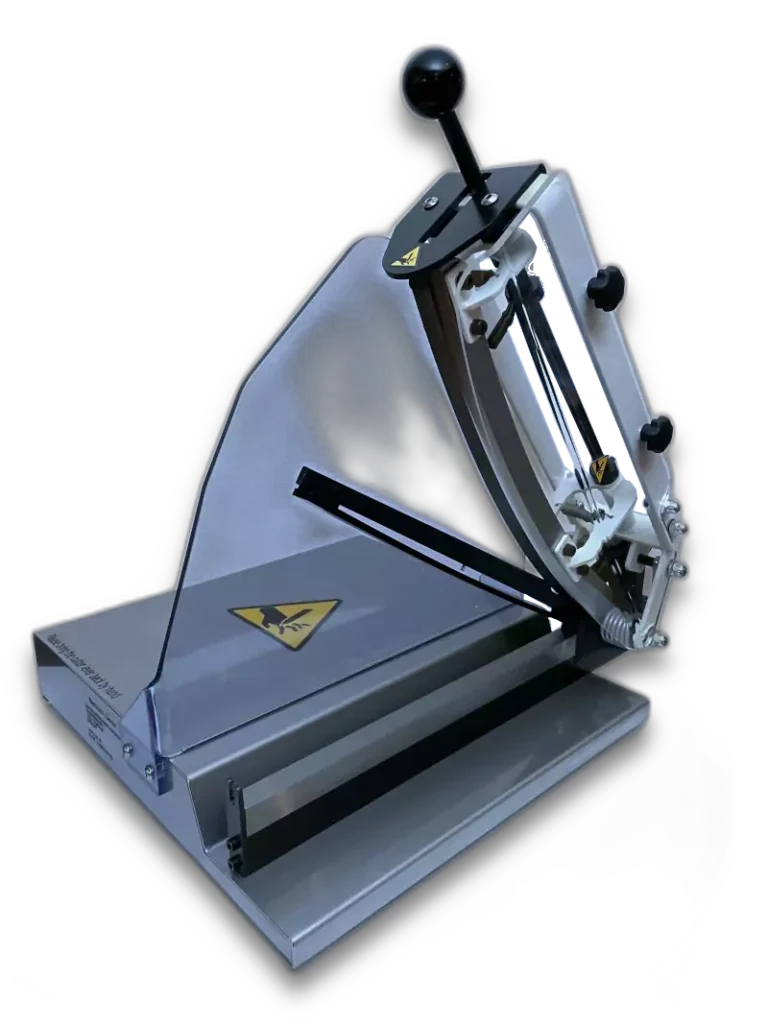

Tried and tested precision sample cutter

Our strip cutter CUT 7 is a sample cutter with a double knife for the production of parallel samples in one operation. We have been manufacturing these sample scissors since 1965 and have satisfied customers all over the world thanks to our high quality. Our strip cutter produces a precise and clean cut with a hold-down device guided by cam discs and spring-loaded upper knives.

Why Cut7?

Precision

The CUT 7 was specially developed for sample preparation of thin, flat materials such as aluminium, copper or brass foil, paper, fleece, textiles and the like.

Quality

We only use the best materials in our production. Fine adjustment during assembly reduces wear on the blades to a minimum.

Sustainability

These sample cutters literally last a lifetime. We still get devices from the early years (1965) for maintenance, which are still doing their job for the customers without any problems.

Just better

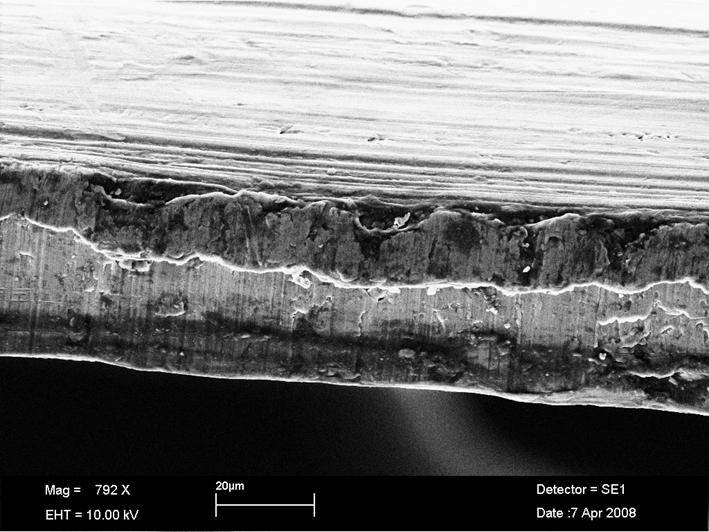

In direct comparison to the sample cutters on the market, the cut surface of the Cut 7 has almost no breakage area.

The consistently clean cut surface has a direct influence on tensile tests, since poor cut surfaces with a high proportion of fractures cause a notch effect and therefore cannot deliver clean, usable results.

The thinnest of metal foils, as well as copper down to 4 µm and coated and uncoated separator foils used in battery production, can be cut with excellent quality.

300mm

15mm

8-30g/m²

Specification

Circular knife with spring bearing for a precise, clean cut. Hold-down device guided by cam discs

For materials with density between 8-30g/m²

Fixes the material to be cut and thus prevents injuries

Precise cutting with rounded blades. Highest level of parallelism Cutting Tests thanks to parallel cutting edges

350 x 550 x 350 mm (L x W x H). Weight approx. 12kg

Highest precision

For the perfect cut

Specially developed for flat materials between 8-30g/m²: aluminum, copper, brass foil, paper, fleece, textiles and the like.